In large scale graphics projects, quality control is not just a process; it’s a critical factor that determines the success and longevity of the project. From the initial design phase to the final installation, maintaining high standards of quality ensures that the end result meets or exceeds expectations. This article delves into why quality control is essential in large scale graphics projects and how it impacts the overall outcome.

Ensuring Consistency Across the Project

One of the primary reasons for stringent quality control in large scale graphics projects is to ensure consistency across all elements. In a project involving extensive graphics, such as murals, billboards, or large event displays, every component must align with the overall design vision.

Uniformity in Design

Quality control helps maintain uniformity in design elements, including color, typography, and imagery. This consistency is crucial for brand recognition and visual impact, ensuring that all graphics work together harmoniously to convey a cohesive message.

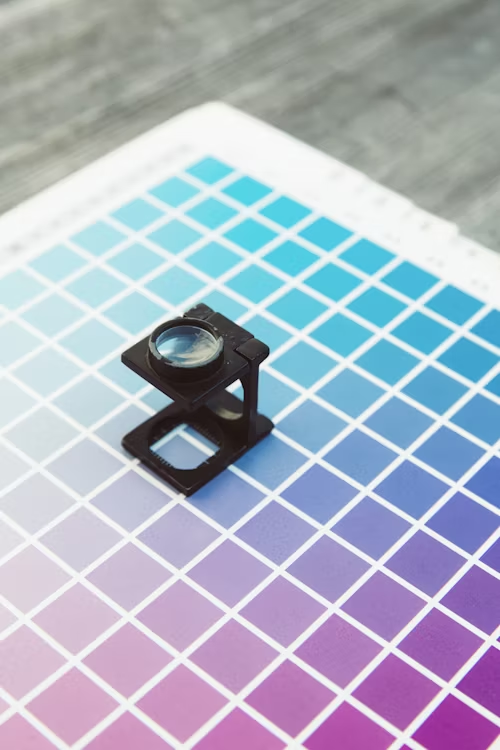

Accurate Color Matching

In large scale graphics, color accuracy is vital. Variations in color can detract from the intended message and affect the project’s overall aesthetic. Quality control processes include rigorous checks to ensure that colors match the specifications exactly, regardless of the size or material of the graphics.

Preventing Errors and Rework

Errors in large scale graphics projects can be costly, both in terms of time and resources. Quality control helps to identify and address issues before they escalate, reducing the likelihood of costly rework.

Early Detection of Issues

Implementing quality control measures at various stages of the project allows for early detection of potential issues. This proactive approach helps to address problems before they become significant, minimizing disruptions and ensuring that the project stays on track.

Minimizing Waste

By catching errors early, quality control helps to minimize waste of materials and resources. This not only reduces costs but also contributes to a more environmentally friendly project by reducing the amount of discarded materials.

Enhancing Durability and Longevity

Large scale graphics are often exposed to various environmental factors, which can impact their durability and longevity. Quality control ensures that the materials and processes used can withstand these conditions and maintain their appearance over time.

Material Selection and Testing

Selecting the right materials for a graphics project is crucial for its durability. Quality control involves testing materials to ensure they meet the required standards for factors such as UV resistance, weather resistance, and adhesion. This ensures that the graphics will remain in good condition despite exposure to the elements.

Proper Installation

The installation process is just as important as the design and production phases. Quality control during installation ensures that the graphics are applied correctly, with no bubbles, wrinkles, or misalignment. Proper installation is essential for the longevity and effectiveness of the graphics.

Meeting Client Expectations

Quality control plays a significant role in meeting and exceeding client expectations. For large scale graphics projects, clients often have specific requirements and standards that must be met.

Adhering to Specifications

Quality control processes involve regular checks to ensure that all aspects of the project adhere to the client’s specifications. This includes verifying dimensions, colors, and design elements to ensure they align with what was agreed upon.

Client Approval and Feedback

Incorporating client feedback into the quality control process is essential for achieving a successful outcome. Regular reviews and approvals help to ensure that the project meets the client’s vision and requirements, leading to higher satisfaction and a more successful final product.

Maintaining Professional Standards

Implementing quality control measures reflects a commitment to maintaining high professional standards in all aspects of the project. This not only enhances the final product but also builds trust and credibility with clients.

Professional Expertise

Quality control requires a skilled team with expertise in various aspects of graphics production, including design, printing, and installation. By employing professionals with the right skills and knowledge, you ensure that every element of the project meets industry standards.

Commitment to Excellence

A robust quality control process demonstrates a commitment to excellence and attention to detail. This commitment is reflected in the final product, which not only meets but often exceeds client expectations.

Conclusion

Quality control is a crucial component of large scale graphics projects, ensuring consistency, preventing errors, enhancing durability, and meeting client expectations. By implementing rigorous quality control measures throughout the design, production, and installation phases, you can achieve a high-quality result that stands the test of time.

GRAPHICS GROUP – The Group of Graphics Companies – is your trusted partner for large scale graphics projects. Our team of experts is dedicated to delivering exceptional results through comprehensive quality control processes, ensuring that your graphics projects are executed to the highest standards. Contact GRAPHICS GROUP today to learn more about how we can help you achieve your vision with precision and excellence.